Inquire Here :

Description

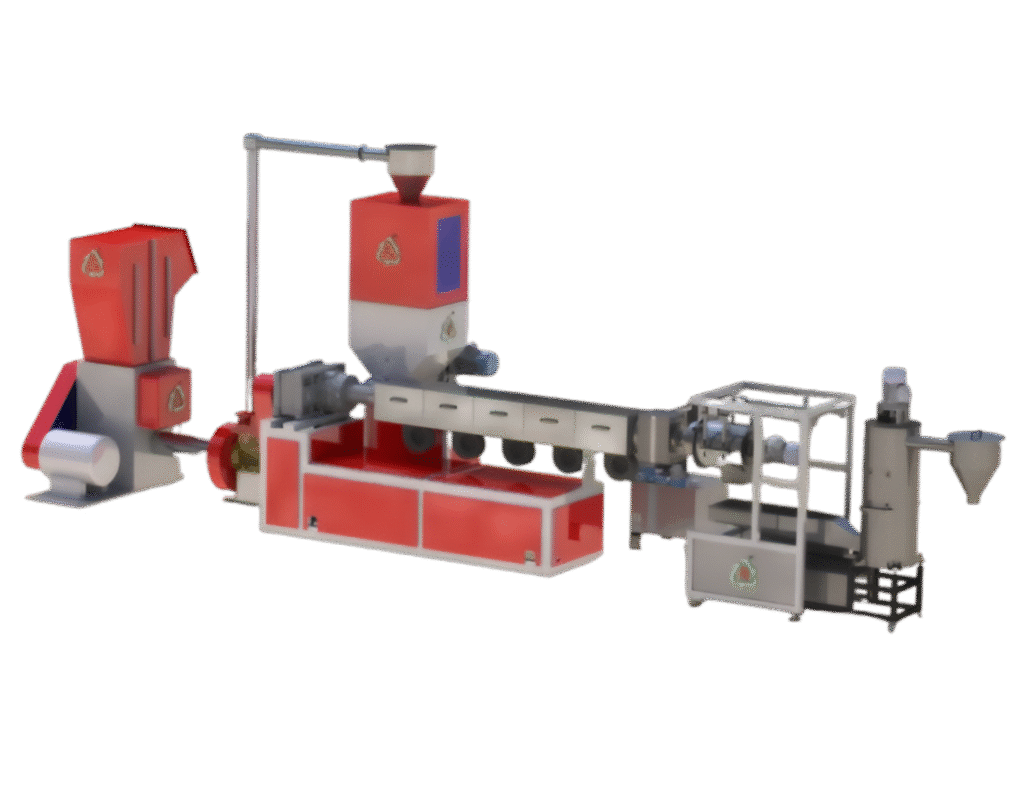

A Single Stage Vented Recycling Plant With Die Face Cutter is a high-performance system designed to process and convert plastic waste—especially film-based materials—into uniform, high-quality granules in one efficient step. This advanced recycling solution is particularly suitable for materials such as LDPE, LLDPE, printed films, and moisture-laden plastics. By integrating feeding, shredding, melting, venting, and pelletizing, the system efficiently removes moisture and volatile contaminants. The die face cutter ensures smooth, consistently sized pellets ideal for reuse in manufacturing.

Equipped with precision venting technology and automated temperature control, the Single Stage Vented Recycling Plant With Die Face Cutter offers maximum processing efficiency while minimizing material degradation. Designed for industrial-scale applications, it significantly reduces energy usage, labor costs, and space requirements. The die face cutting system simplifies the pelletizing process by producing uniform granules with minimal manual handling.

Features

- Extrusion System

- Control Systems

- Material Compatibility

- Cooling Systems

- Versatility and Customization

Application

PVC GARDEN PIPE

BUBBLE FILM

BAGS

PE/PP FILM ROLL

Stretch Film

Garbage Bag

road waste

Plastic Drum

Videos

Technical Specification

| PLANT MODEL | HRPI-75 | HRPI-90 | HRPI-100 | HRPI-110 | HRPI-120 |

|---|---|---|---|---|---|

| OUTPUT ARTICLE WASTE (LDPE/HDPE/PP) | 80-110 KG/HR | 130-160 KG/HR | 160-200 KG/HR | 200-280 KG/HR | 350-450 KG/HR |

| RUNNING LOAD | 37 KW | 50KW | 44KW | 52KW | 85KW |

Materials

- PP DANA

- HD DANA

- LD DANA

- PVC CABLE DANA

- PE

- PP

- PVC

- PET

- PS