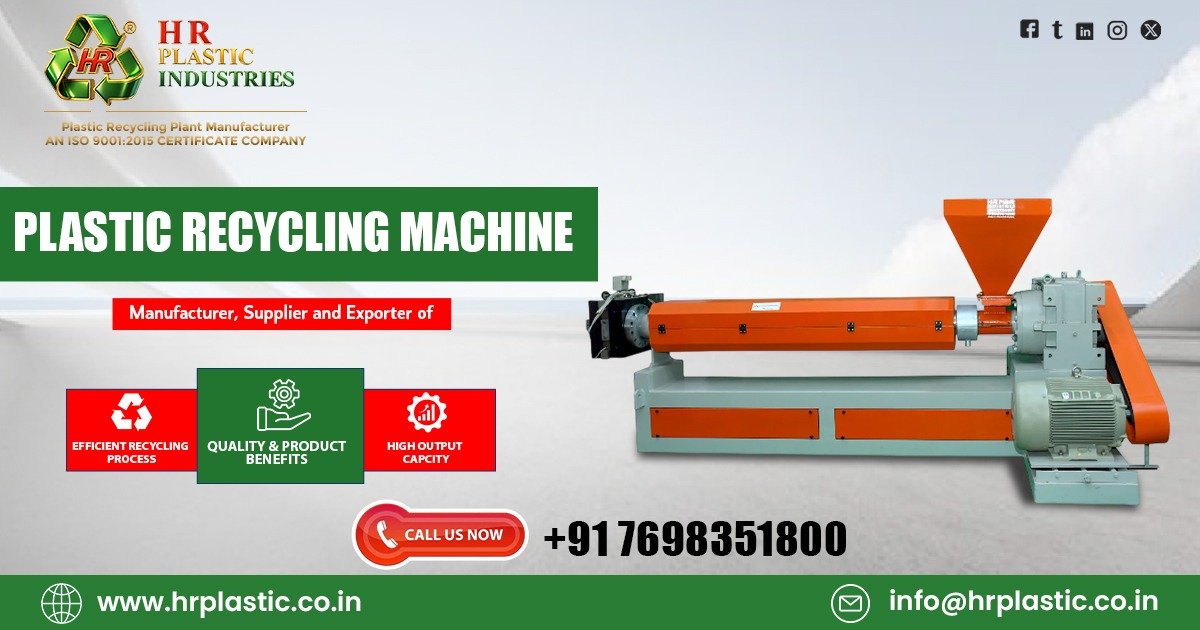

H.R. Plastic Industries is a reliable Manufacturer, Supplier and Exporter of Plastic Granules Making Machine in United States.

Our Manufacturing unit is based in Ahmedabad, Gujarat, India.

A Plastic Granules Making Machine in the United States is essential for recycling plastic waste into reusable granules.

These high-performance machines are built to meet American industry standards, delivering precision, energy efficiency, and high output.

They support a wide range of industries, including packaging, automotive, construction, and consumer goods.

For manufacturers looking to reduce production costs and support eco-friendly operations, a plastic granules making machine is a smart investment.

Why Choose Us?

U.S.-Standard Quality: Our machines are manufactured following strict American engineering guidelines, guaranteeing long service life and stable performance.

Advanced Technology: We integrate cutting-edge automation, temperature control, and filtration systems for consistent granule quality.

Energy-Efficient Design: Our machines consume less power while delivering higher productivity, reducing operational costs.

Customizable Solutions: We provide tailored solutions suitable for different plastic types—HDPE, LDPE, PP, ABS, PET, PVC, and more.

Reliable After-Sales Support: We offer installation assistance, operator training, maintenance support, and readily available spare parts across the United States.

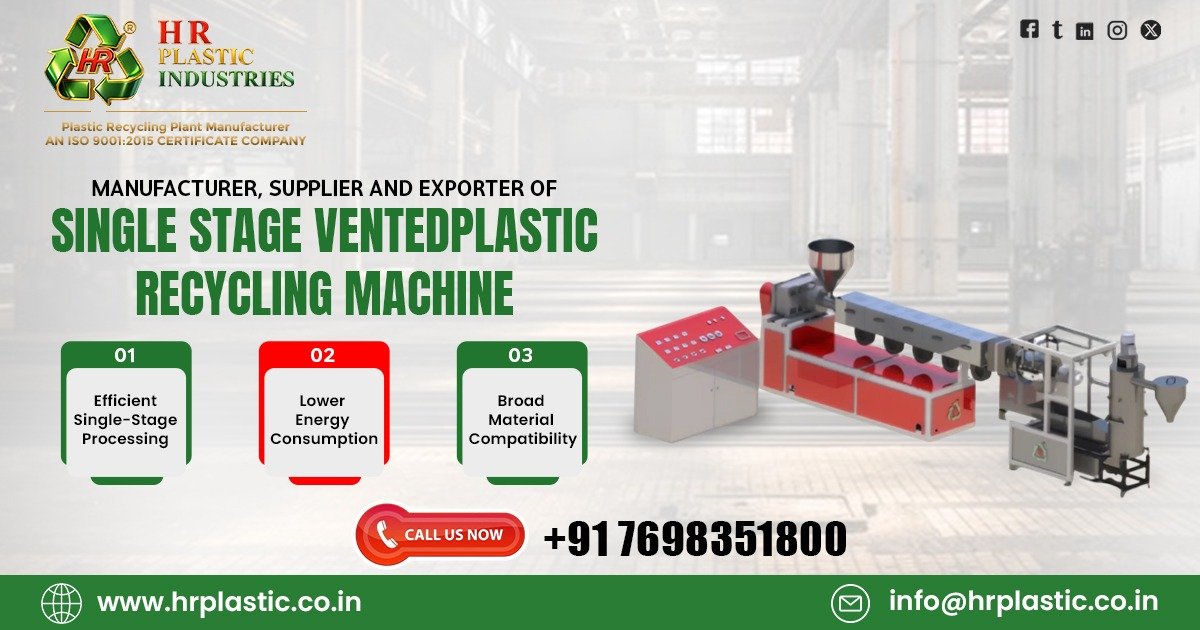

Features of Plastic Granules Making Machine

- High-Capacity Extruder: Ensures continuous and smooth plastic melting.

- Superior Screw & Barrel Design: Provides uniform melting, mixing, and homogenization.

- Efficient Cooling System: Maintains stable temperatures for consistent granule shape.

- Advanced Filtration Unit: Removes impurities for premium-grade recycled granules.

- Automatic Cutter & Pelletizer: Produces uniform-size granules for downstream processing.

- Robust Build Quality: Heavy-duty steel construction for long-term industrial use.

- User-Friendly Control Panel: Digital display with automatic temperature and speed control.

- Low Noise & Low Maintenance: Designed to operate smoothly with minimal downtime.

- Versatile Material Compatibility: Recycles plastic films, scraps, flakes, and rigid plastics.

Working Principle of Plastic Granules Making Machine

- Feeding

- Plastic waste is fed into the hopper manually or through an automatic conveyor.

- Melting & Extrusion

- The screw inside the extruder rotates, heating and melting the plastic material uniformly.

- Filtering

- Melted plastic passes through a filter screen to remove dust, metal, and impurities.

- Strand Formation

- The molten plastic is pushed through a die to form long strands.

- Cooling

- The strands pass through a water bath or air-cooling system for stabilization.

- Pellet Cutting

- A rotary cutter or die-face cutter chops the strands into small granules.

- Drying & Collection

- Granules are dried and collected for packaging or further processing.

Applications of Plastic Granules Making Machine

- Plastic Recycling Plants

- Packaging Industry

- Automotive Plastic Parts Production

- Pipe and Fitting Manufacturing

- Household Products Manufacturing

- Film and Sheet Production

- Electrical & Electronic Components

- Construction Materials (PVC, HDPE pipes, profiles)

This machine is ideal for converting plastic waste into high-quality granules used to produce bags, containers, films, components, and more.

FAQs

1. What types of plastics can be processed?

The machine can recycle HDPE, LDPE, LLDPE, PP, ABS, PVC, PET, and various mixed plastic wastes.

2. What is the production capacity?

Capacity ranges from 100 kg/hr to 2000+ kg/hr, depending on the model and customization.

3. Do you offer installation support in the United States?

Yes, we provide full installation, training, and technical assistance across the U.S.

4. How energy efficient are these machines?

Our systems use optimized heaters, motors, and gearboxes to reduce power consumption by 15–30%.

5. What is the lifespan of the machine?

With proper maintenance, the machine typically lasts 8–15 years or longer.

6. Can the machine be customized?

Absolutely—screw size, motor capacity, cutter type, and filtration systems can be customized per your production needs.

7. Is the machine easy to operate?

Yes, it includes an intuitive control panel and automated systems for easy operation and minimal supervision.

H.R. Plastic Industries is an Exporter of Plastic Granules Making Machine in United States and including locations in Los Angeles, Phoenix, Austin, New York, San Antonio, Chicago,

Houston, Dallas, San Diego, Philadelphia, Oklahoma City, Salt Lake City, Baltimore, Detroit, Kansas City, San Francisco, Kansas City, Columbus, Denver, Indianapolis, San Jose, Seattle,

Charlotte, Las Vegas, Jacksonville, El Paso, Baton Rouge, Atlanta, Raleigh, Sacramento, Fort Worth, Nashville, Albuquerque, Little Rock, Madison, Des Moines, Columbia, Boston,

Montgomery, Tucson, Memphis, Milwaukee, Boise, Lincoln, Jackson, Tulsa, Colorado Springs, Omaha, Louisville, Tallahassee, Fresno and many

more.

For more information and inquiries, feel free to contact us.

Visit: www.hrplastic.co.in

Email: info@hrplastic.co.in, sales@hrplastic.co.in

Call: +91 95102 05025

View Product: Click here