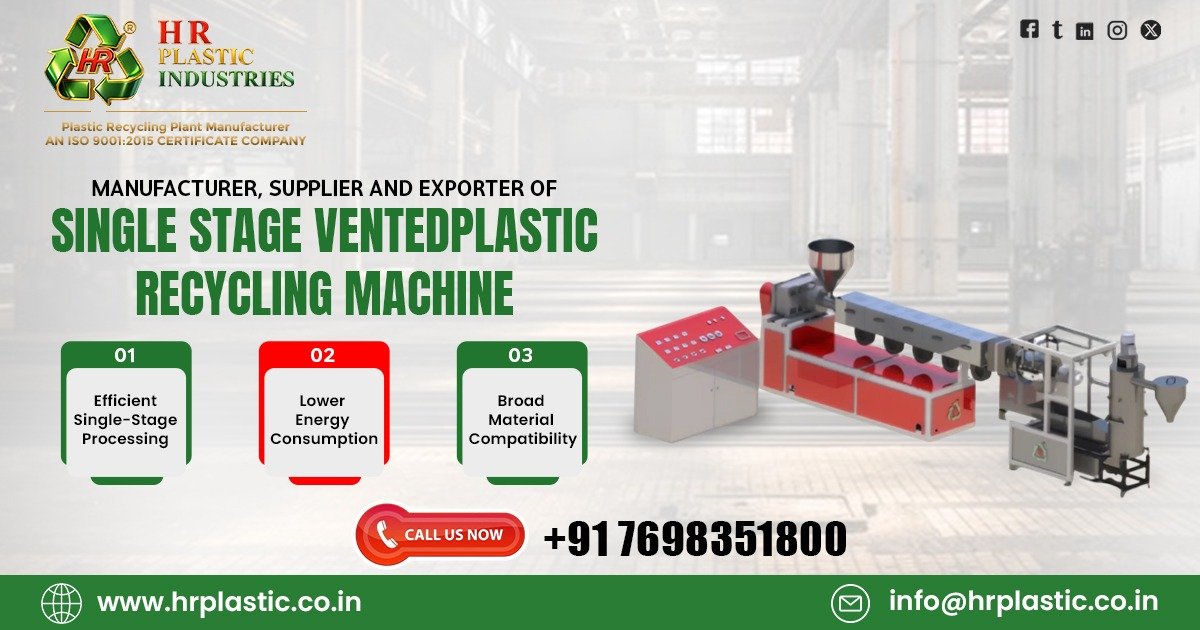

H.R. Plastic Industries is a trusted Manufacturer, Supplier and Exporter of Single Stage Vented Plastic Recycling Machine in South Korea.

Our Manufacturing unit is based in Ahmedabad, Gujarat, India.

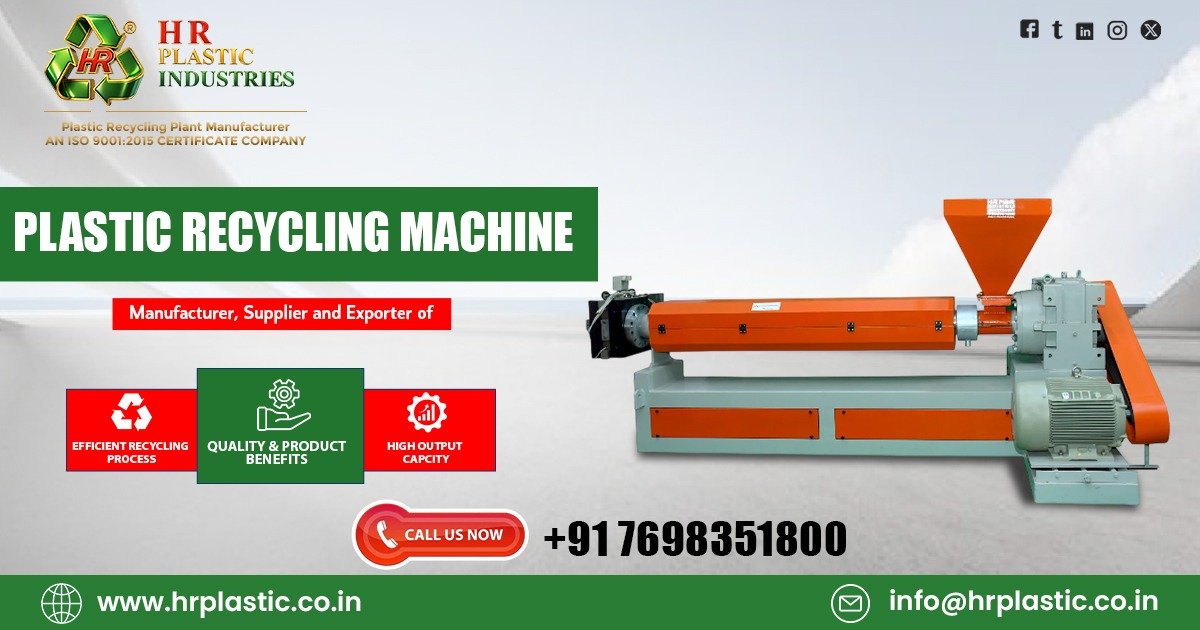

The Single Stage Vented Plastic Recycling Machine efficiently melts, filters, and pelletizes PET, HDPE, LDPE, and PP continuously.

This machine is ideal for small- and medium-scale recycling, offering compact design, energy efficiency, and easy maintenance.

The extrusion screw consistently melts and shears plastic, controlling the molten plastic’s temperature and viscosity precisely.

A vent port along the barrel allows efficient degassing, preventing bubbles, black specks, and defects in the final product.

The machine filters impurities, cools extruded plastic strands with air or water, and pellets them into uniform granules.

These granules are reusable in injection molding, blow molding, and extrusion, providing industries a sustainable alternative to virgin plastic.

Typical Output & Performance:

H.R. Plastic Industries’ Single Stage Vented Plastic Recycling Machines are designed for efficiency, durability, and consistent pellet quality.

HRPI‑75: 80–110 kg/hr | 37 kW – Ideal for small-scale recycling units.

HRPI‑90: 130–160 kg/hr | 50 kW – Reliable for medium operations.

HRPI‑100: 160–200 kg/hr | 44 kW – Suitable for moderate-volume industrial use.

HRPI‑110: 220–280 kg/hr | 52 kW – Perfect for medium-to-large recycling plants.

HRPI‑120: 350–450 kg/hr | 85 kW – High-capacity model for large-scale industrial recycling.

All models feature vented extrusion, energy-efficient motors, and low maintenance, ensuring high-quality output and reliable operation for plastic recycling businesses.

Working Process:

Feeding – Operators load plastic waste (films, bags, containers) into the hopper during the feeding process.

Melting – Waste enters the screw extruder where friction and heating melt the plastic uniformly.

Venting / Degassing – Moisture, gases, and volatile contaminants pass through the vented section for removal during venting and degassing.

Filtration – Melted plastic passes through a screen or filter to remove solid impurities.

Extrusion – The machine pushes clean, degassed plastic through the die to form strands during extrusion.

Cooling – Strands are cooled using water or air to solidify.

Pelletizing – A die-face cutter or strand pelletizer cuts solidified strands into uniform pellets during pelletizing.

Collection – Recycled pellets are collected for reuse in manufacturing processes.

Features of Single Stage Vented Plastic Recycling Machine:

Single-stage extrusion system

Vented barrel for efficient degassing

Energy-efficient motor and screw design

Adjustable temperature control for various plastics

Low maintenance and long operational life

User-friendly control panel for easy operation

Compact footprint suitable for medium-scale recycling units

High-quality granule output with uniform size

Robust construction for industrial durability

Quick startup and shutdown for operational convenience

Integrated filtration system for impurity removal

Compatible with multiple plastic types (PET, HDPE, LDPE, PP)

Applications:

The Single Stage Vented Plastic Recycling Machine is suitable for industries such as:

Plastic Film Manufacturing

Packaging Industry

Plastic Bag Production Units

Blow Moulding & Injection Moulding Plants

Recycling Plants Handling LDPE/HDPE/PP Waste

Post-Industrial Plastic Waste Processing

Agricultural Film Recycling

Household Plastic Waste Reprocessing

Frequently Asked Questions (FAQ):

Q1. Can it process post-consumer plastic waste?

Yes, washed post-consumer flakes and films can be processed if contamination and moisture are adequately managed.

Q2. How is the machine powered?

Industrial electric motors drive the screw extruder and auxiliary systems efficiently for continuous operation.

Q3. What maintenance does the machine require?

Regular cleaning, screw inspection, and filter replacement ensure consistent performance and longer equipment lifespan.

Q4. Is the machine automated?

Modern units feature automated temperature, screw speed, and pelletizing controls for efficient operation.

H.R. Plastic Industries is an Exporter of Single Stage Vented Plastic Recycling Machine in South Korea and including locations in Seoul, Busan, Incheon, Daegu, Gwangju, Daejeon, Suwon, Ulsan, Tongjin, Goyang, Changwon, Sŏngnam, Bucheon, Anyang, Gwangmyeongni, Kunp’o, Guri, Dongnae.

For more information and inquiries, feel free to contact us.

Visit: www.hrplastic.co.in

Email: info@hrplastic.co.in, sales@hrplastic.co.in

Call: +91 95102 05025

View Product: ClickHere