H.R. Plastic Industries is leading manufacturer and exporter of Automatic Plastic Granules Making with Die Face Cutter in United States.

Our Manufacturing unit is based in Ahmedabad, Gujarat, India.

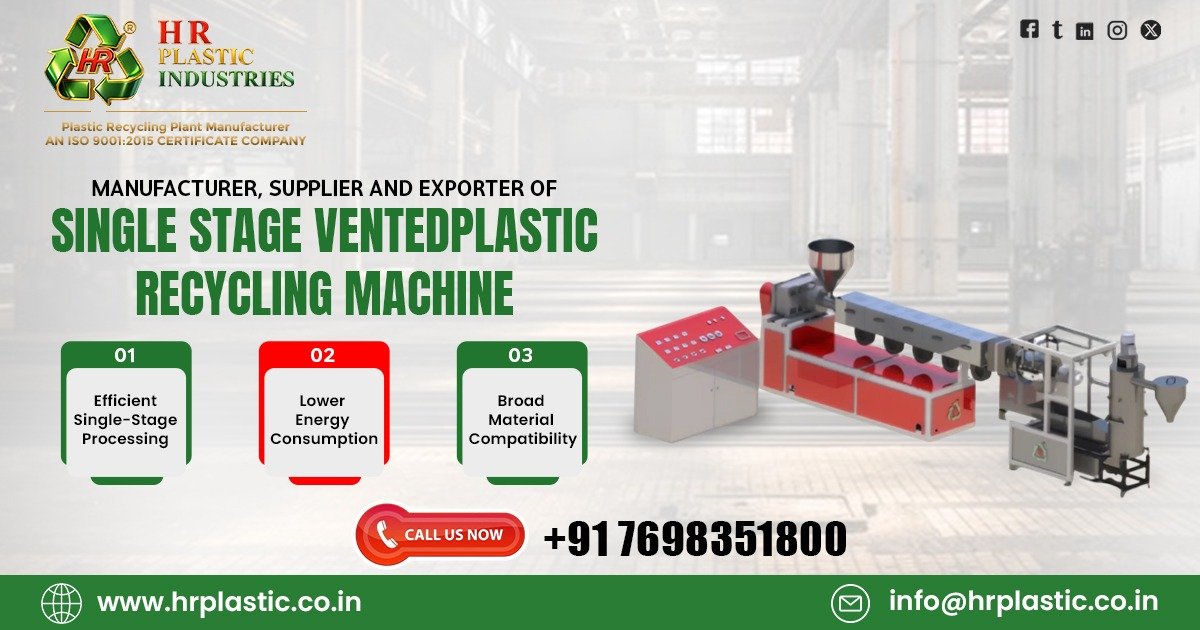

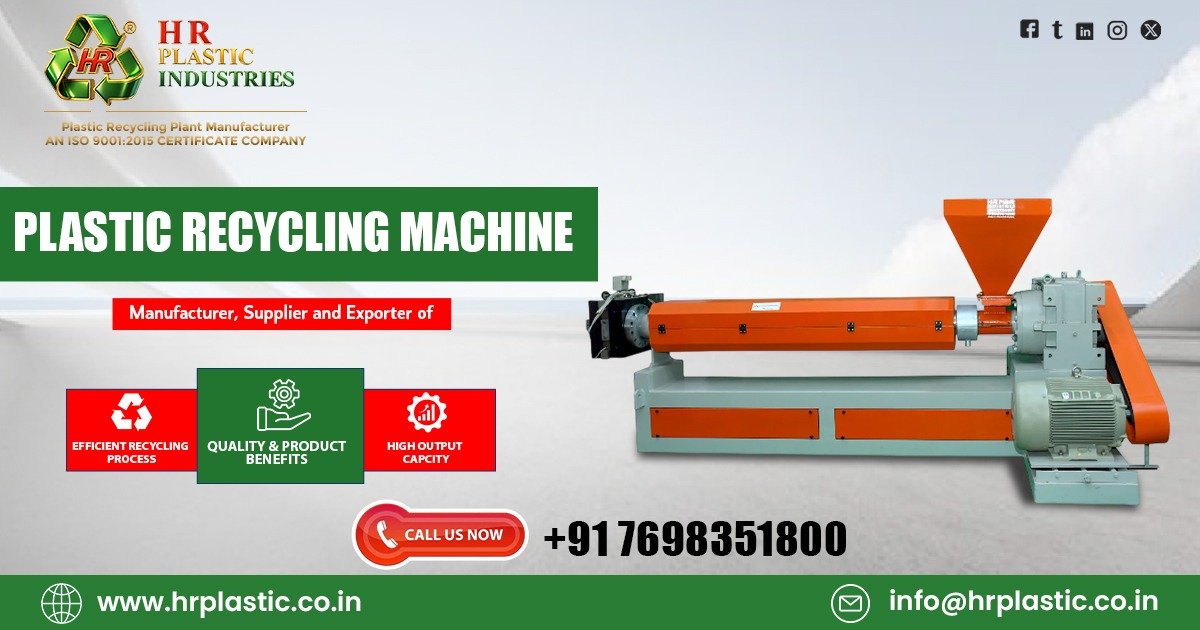

H.R. Plastic Industries specialize in providing high-performance plastic processing machinery that sets new benchmarks in productivity and efficiency.

One of our flagship solutions, the Automatic Plastic Granules Making Machine with Die Face Cutter, is engineered to convert plastic waste into uniform, high-quality granules with minimal human intervention.

Designed for recycling and manufacturing units, this machine combines automation, precision, and sustainability in a single powerful system.

Whether you’re working with HDPE, LDPE, PP, or other thermoplastics, this system is your answer to seamless granulation with optimal output.

Work of Automatic Plastic Granules Making with Die Face Cutter

The Automatic Plastic Granules Making Machine with Die Face Cutter operates through a continuous and efficient plastic recycling process:

- Feeding & Extrusion: Waste or virgin plastic is fed into the extruder where it is melted uniformly.

- Filtration: The molten plastic is filtered to remove contaminants or impurities.

- Die Face Cutting: The melted plastic exits through a die plate and is instantly cut into granules using a rotary cutter located at the die face.

- Cooling: The granules are air- or water-cooled as they come out of the cutter.

- Drying & Collection: Finally, the granules are dried and collected for packing and reuse.

This automatic operation reduces manual handling, improves granule quality, and ensures consistent production.

Features of the Machine

- Fully Automatic Operation

Minimal human input with automated feeding, cutting, and drying processes. - Integrated Die Face Cutter System

Produces uniform-sized granules instantly during extrusion. - High Output Efficiency

Capable of processing large volumes with consistent performance. - Energy Efficient Design

Built with energy-saving components and smart engineering. - Robust Construction

Made from durable materials for long service life and minimal maintenance. - Multi-material Compatibility

Works with a wide range of plastic types including HDPE, LDPE, LLDPE, and PP. - Touchscreen Control Panel (Optional)

For easy monitoring and control of parameters like temperature, speed, and pressure.

Benefits of Using Die Face Cutter Granule Machines

- Increased Production Speed

Continuous granule output without needing manual pelletizing. - Eco-Friendly Recycling

Supports plastic waste management by converting waste into reusable granules. - Reduced Labor Costs

Full automation lowers the need for multiple operators. - Consistent Granule Quality

Uniform size and shape suitable for high-end plastic product manufacturing. - Easy Maintenance

Modular design ensures components can be cleaned or replaced with ease.

Uses and Applications

Our Automatic Plastic Granules Making Machine with Die Face Cutter is ideal for:

- Plastic recycling plants

- Plastic film manufacturing units

- Pipe and profile extrusion industries

- Injection molding units

- Packaging and bag making industries

- Masterbatch and compounding units

Manufacturers reuse the granules produced by the machine to make plastic sheets, pipes, containers, films, and more.

Frequently Asked Questions (FAQs)

Q1. What materials can be processed with this machine?

A: This machine is compatible with various thermoplastics including LDPE, HDPE, LLDPE, PP, and more.

Q2. What is the output capacity of the machine?

A: Output varies by model, but typically ranges from 100 kg/hr to 1000+ kg/hr depending on configuration.

Q3. Is the die face cutter adjustable?

A: You can adjust the die face cutter for precision based on the desired granule size.

Q4. Does it require a water tank for cooling?

A: The machine supports both air and water cooling systems depending on user preference and production requirements.

H.R. Plastic Industries is an Exporter of Automatic Plastic Granules Making with Die Face Cutter in United States including locations in New York, Austin, Los Angeles,

Chicago, Phoenix, Philadelphia, Houston, San Diego, San Antonio, Dallas, Salt Lake City, Oklahoma City, San Francisco, Baltimore, Nashville, Denver, Columbus, San Jose,

Seattle, Atlanta, Charlotte, Las Vegas, Raleigh, Tucson, Orlando, Boston, Madison, Indianapolis, Portland, Milwaukee, Omaha, Tampa, New Orleans, Charleston, Albany,

Baton Rouge, Fort Worth, Jacksonville, Albuquerque, El Paso, Anchorage, Honolulu, Sacramento, Arlington, Amarillo, Miami, Washington, D.C., Abilene, Augusta,

Detroit, Providence

Contact us today to learn more or request a quote.