Looking for a high-performance Plastic Dana Making Machine in Odisha?

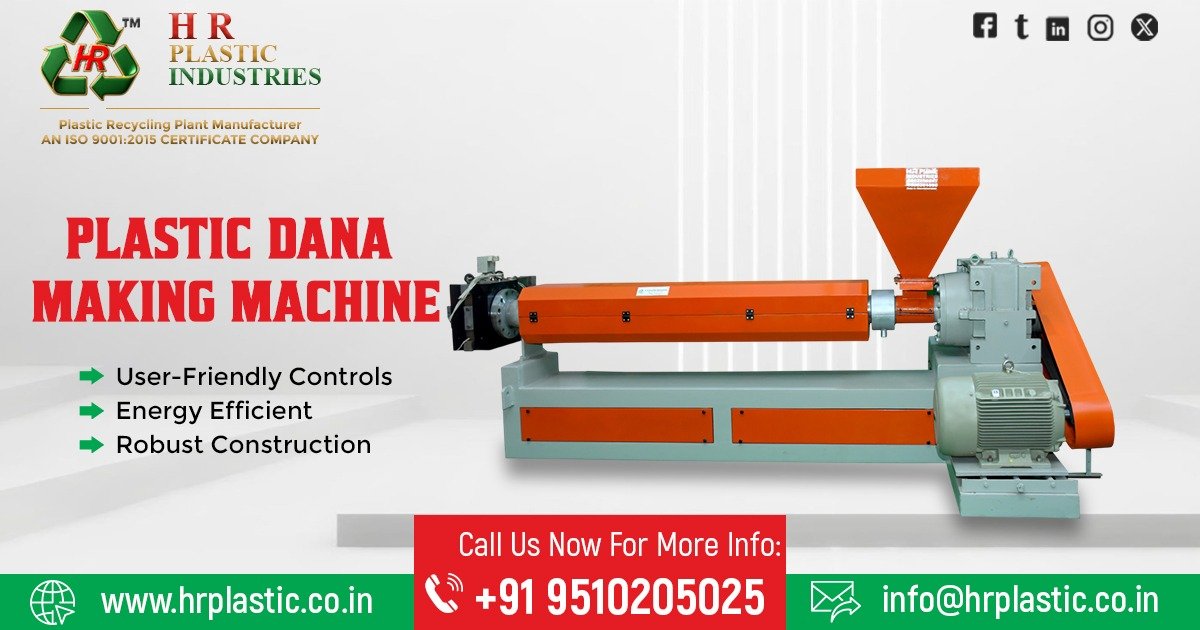

H.R. Plastic Industries specialize in manufacturing and supplying advanced plastic recycling machinery, including top-quality Plastic Dana Making Machines that meet industrial

demands with precision and efficiency.

We are based in Ahmedabad, Gujarat, India.

We engineer our machines for durability, energy efficiency, and seamless operation, making them ideal for businesses involved in plastic waste recycling, granule production,

and polymer processing.

With rising demand for sustainable plastic solutions, our machines are empowering manufacturers across Odisha to recycle and reuse plastic in an

eco-friendly manner.

Features of Plastic Dana Making Machine

Our Plastic Dana Making Machines are designed with cutting-edge technology and built using premium-grade components.

Below are the key features:

- Robust Construction: Heavy-duty steel body ensures long-lasting performance.

- High Output Capacity: Efficient granulation for large-scale production.

- Energy Efficient: Low power consumption with optimized motor design.

- User-Friendly Interface: Easy to operate and maintain with minimal training.

- Screw & Barrel Assembly: Nitrided or alloy steel options for enhanced durability.

- Temperature Control: Automatic digital control panel for heat regulation.

- Customizable Design: Available in single or twin screw models, depending on requirement.

- Low Maintenance Cost: Reliable performance with minimal wear and tear.

Work of Plastic Dana Making Machine

A Plastic Dana Making Machine converts plastic waste into reusable plastic granules (known as dana), which manufacturers then use to produce various plastic products.

Here’s how it works:

- Plastic Feeding: Operators load waste plastic material (HDPE, LDPE, PP, etc.) into the hopper.

- Melting Process: A heated screw barrel conveys the plastic and melts it uniformly.

- Filtration: Mesh filters remove impurities to ensure pure granule production.

- Extrusion: The machine extrudes molten plastic through a die to form strands.

- Cooling: A water bath or air-cooled system cools the strands.

- Pelletizing: A pelletizer chops the strands into uniform plastic granules (dana).

Application

Our Plastic Dana Making Machines are widely used across various industries for:

- Plastic Recycling Units

- Plastic Bottle and Film Reprocessing

- Injection Moulding and Blow Moulding Units

- Municipal Waste Plastic Management

- Carry Bag and Packaging Material Manufacturing

- Industrial Plastic Scrap Reprocessing

Whether you’re a small-scale recycler or a large industrial plant, H.R. Plastic Industries offers customized solutions to meet your recycling goals.

FAQs

1. What types of plastic can be processed in a Plastic Dana Making Machine?

Our machines can process a wide range of plastics, including HDPE, LDPE, LLDPE, PP, ABS, and more.

2. What is the production capacity of your Plastic Dana Making Machines?

We offer machines with output capacities ranging from 50 kg/hr to 500 kg/hr, depending on your requirement.

3. Do you offer installation and training support in Odisha?

Yes, we provide on-site installation, operator training, and after-sales service across Odisha and nearby states.

4. How much space is required for setting up the machine?

Space requirements vary based on the model. On average, a minimum of 500–1000 sq. ft. is recommended for setup and operation.

H.R. Plastic Industries is a Supplier of Plastic Dana Making Machine in Odisha including locations in Bhubaneswar, Cuttack, Rourkela, Berhampur, Sambalpur, Puri, Balasore,

Bhadrak, Baripada, Angul, Balangir, Balasore, Bargarh, Bhadrak, Cuttack, Debagarh, Dhenkanal, Gajapati, Ganjam, Jagatsinghapur, Jajapur, Jharsuguda, Kalahandi, Kandhamal,

Kendrapara, Kendujhar, Khordha, Koraput, Malkangiri, Mayurbhanj, Nabarangpur, Nayagarh, Nuapada, Puri, Rayagada, Sambalpur, Subarnapur, and Sundergarh and many more.

For more information and inquiries, feel free to contact us.

Visit: www.hrplastic.co.in

Email: info@hrplastic.co.in, sales@hrplastic.co.in

Call: +91 95102 05025

View Product: Click here