H.R. Plastic Industries is an exporter of Plastic Granules Making Machine in Colombia.

Our Manufacturing unit is based in Ahmedabad, Gujarat, India.

What is a Plastic Granules Making Machine?

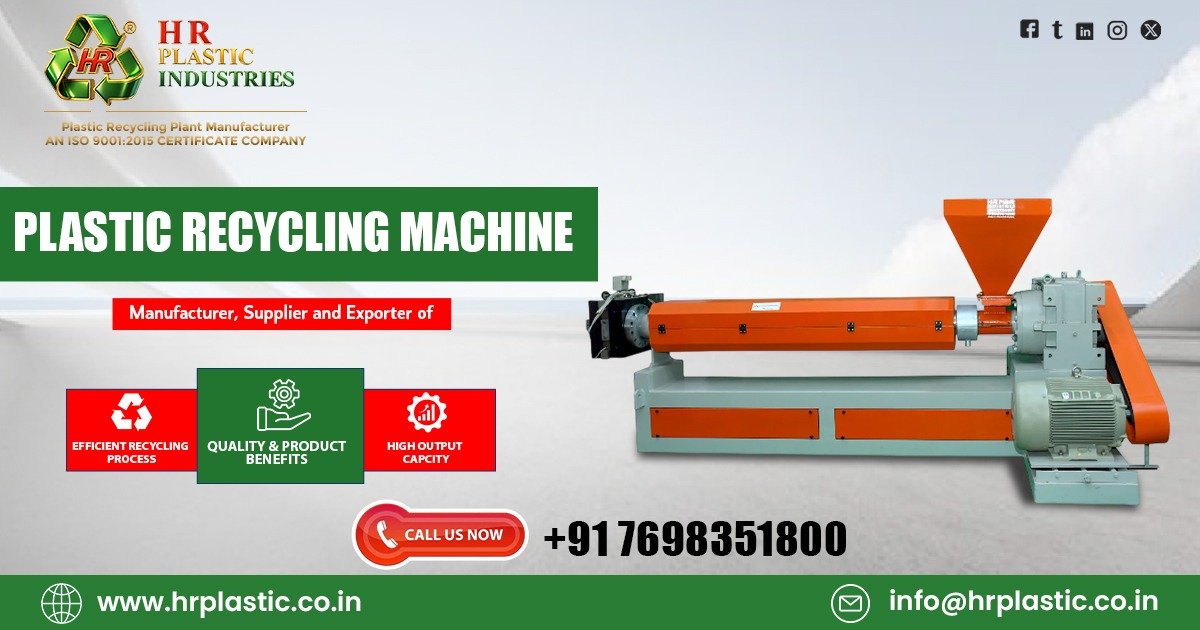

A plastic granules making machine converts raw plastic materials or recycled plastic waste into uniform granules or pellets.

Plastic recycling plants, manufacturing units, and molding industries widely use it to create reusable plastic material for various applications.

The machine works by feeding plastic flakes, chips, or waste into an extruder, where the material is melted, homogenized, and pushed through a die.

A cutting mechanism then slices the extruded plastic into uniform granules, which are subsequently cooled and collected for further processing.

Plastic granules produced by this machine are consistent in size and shape, ensuring high-quality output suitable for molding, extrusion, and other manufacturing processes.

Materials Processed:

Polyethylene (PE): Durable granules for packaging and industrial use.

Polypropylene (PP): Lightweight, high-strength granules for automotive and manufacturing.

Low-Density Polyethylene (LDPE): Flexible granules for films, bags, and packaging.

High-Density Polyethylene (HDPE): Strong granules for pipes, containers, and heavy-duty use.

Other Thermoplastics: PET, PVC, and recycled plastics for versatile granule production.

Why Choose H.R. Plastic Industries?

We have deep expertise and 37+ years of engineering experience in plastic recycling and pelletizing lines — giving you reliable, high-quality machines.

Our machines are built with durable, wear-resistant components (screws/barrels, die heads, cutting blades), to ensure long life and minimal downtime.

We provide automated control systems (PLC/SCADA, screen changers, degassing, recipe control) — giving operational ease and consistent quality.

We provide installation, commissioning, training, and after-sales service, offering turnkey solutions ideal for setting up or expanding a recycling line.We commit to sustainability and a circular economy by helping clients convert plastic waste into high-grade raw materials, reduce costs, and minimize environmental impact.

Our machines are engineered for optimal energy consumption, helping reduce operational costs while maintaining high throughput and consistent output.

Trusted by clients worldwide, we have a history of delivering high-performance machines that boost productivity and profitability.

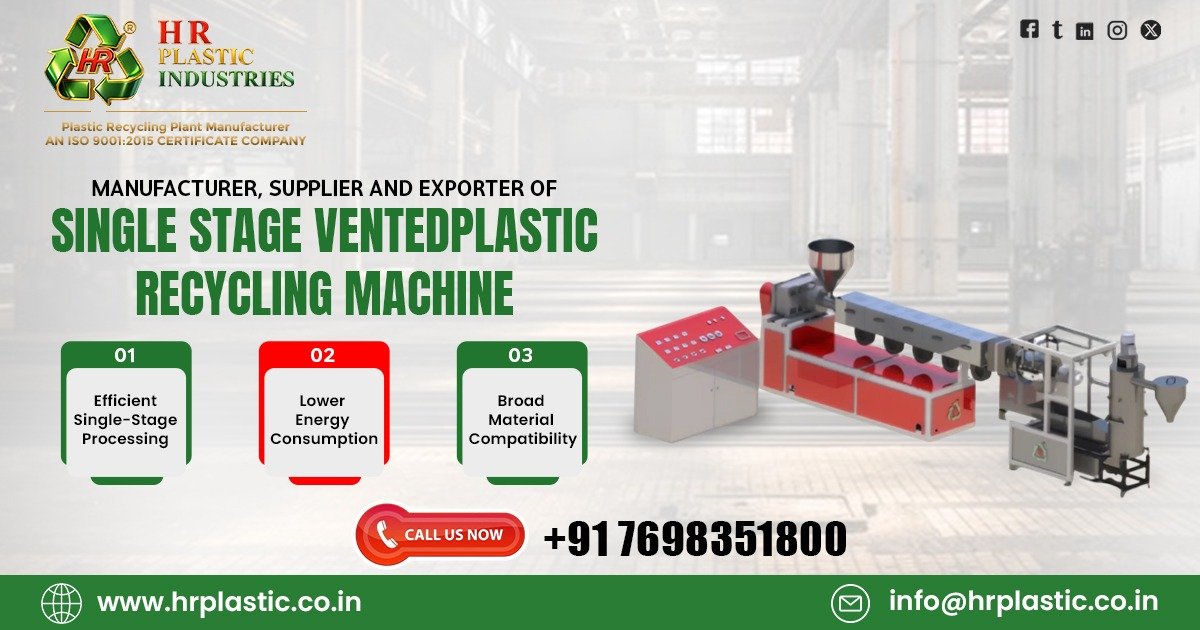

Features of Plastic Granules Making Machine:

High-Precision Extruder: Ensures consistent melting and granulation

Durable Construction: Long-lasting stainless steel and alloy parts

Energy-Efficient: Lowers operational costs while consistently delivering high performance

Automatic Cutting System: Produces uniform granules with adjustable size

Advanced Cooling System: Ensures proper granule solidification

User-Friendly Operation: Simple controls with easy monitoring

Low Maintenance: Minimal downtime with high efficiency

Versatile Processing: Compatible with HDPE, LDPE, PET, PVC, PP, and recycled plastics

Applications of Plastic Granules Making Machine:

Plastic recycling industries

Manufacturing of plastic bottles, pipes, and containers

Plastic molding and extrusion industries

Production of packaging materials

Production of plastic sheets and films

Automotive components manufacturing

Household plastic products production

Industrial plastic parts fabrication

FAQs – Plastic Granules Making Machine:

Q1. Is it energy-efficient?

Yes, optimized screw design, precise heating, and efficient motors minimize energy consumption for cost-effective operation.

Q2. Does it remove impurities?

Yes, filtration, mesh screens, and degassing ensure high-quality, contaminant-free granules suitable for downstream processes.

Q3. What maintenance is required?

Regular cleaning, lubrication, screw inspection, and checking heating/cooling systems ensures longevity and consistent pellet quality.

Q4. Does it support color mixing?

Yes, twin-screw extruders allow compounding, blending pigments, additives, and masterbatches for customized colored granules.

H.R. Plastic Industries is an Exporter of Plastic Granules Making Machine in Colombia including locations in Bogotá, Medellín, Cali, Barranquilla, Cartagena, Bucaramanga, Cúcuta, Palermo, Soledad, Villavicencio, Pereira, Bello, Valledupar, Ibagué, Montería, Soacha, Santa Marta, Manizales, Buenaventura, Pasto, Neiva, Palmira, Fontibón, Usme, Armenia, Popayán, Floridablanca, Sincelejo, Itagüí, Envigado, Tuluá, Tumaco, Barrancabermeja, Uripa, Zipaquirá, Florencia, Turbo, Santander de Quilichao.

For more information and inquiries, feel free to contact us.

Visit: www.hrplastic.co.in

Email: info@hrplastic.co.in, sales@hrplastic.co.in

Call: +91 95102 05025

View Product: Click Here