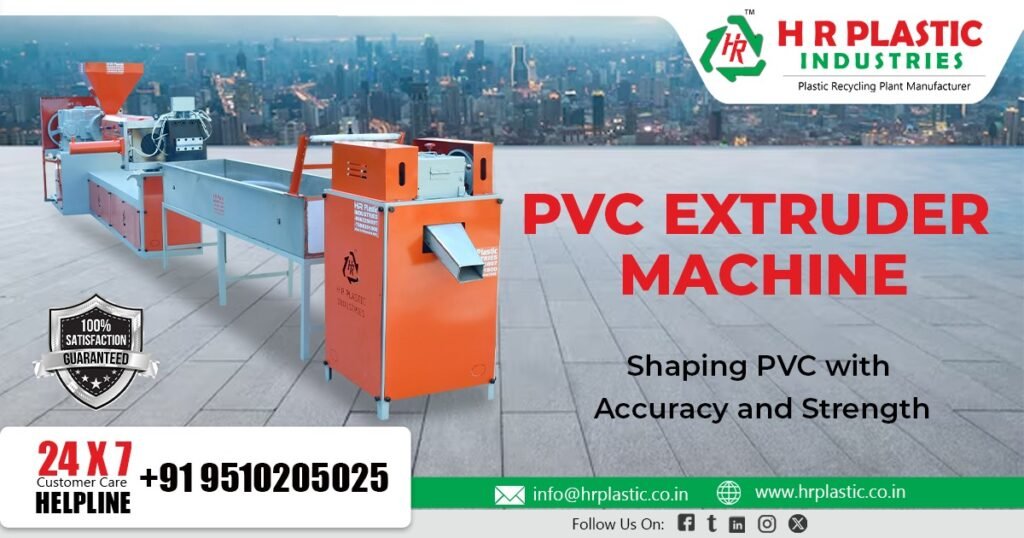

H.R. Plastic Industries is a leading Manufacturer, Supplier and Exporter of PVC Extruder Machine in USA.

Our Manufacturing unit is based in Ahmedabad, Gujarat, India.

H.R. Plastic Industries specialize in delivering robust and efficient PVC extruder machines designed to meet the diverse needs of the plastic

manufacturing industry worldwide.

We engineer our PVC extruder machines to deliver exceptional performance, reliability, and cost-effectiveness, ensuring optimal production for our clients.

Our machines are built using premium-grade materials and cutting-edge manufacturing processes, ensuring durability and consistent performance.

As a seasoned exporter, we understand the intricacies of international trade and provide seamless delivery and support to our clients in the USA.

We offer high-quality machines at competitive prices, providing excellent value for your investment.

Why Choose Our PVC Extruder Machine Features?

High-Efficiency Screw Design: Optimized screw geometry ensures superior plasticization, consistent melt quality, and higher output.

Precise Temperature Control: Advanced PID control systems maintain accurate temperature profiles across all zones, crucial for PVC processing.

Robust Gearbox: Heavy-duty gearbox designed for continuous operation and high torque transmission, ensuring longevity and stable performance.

Energy Efficiency: Designed to minimize power consumption without compromising on production capacity.

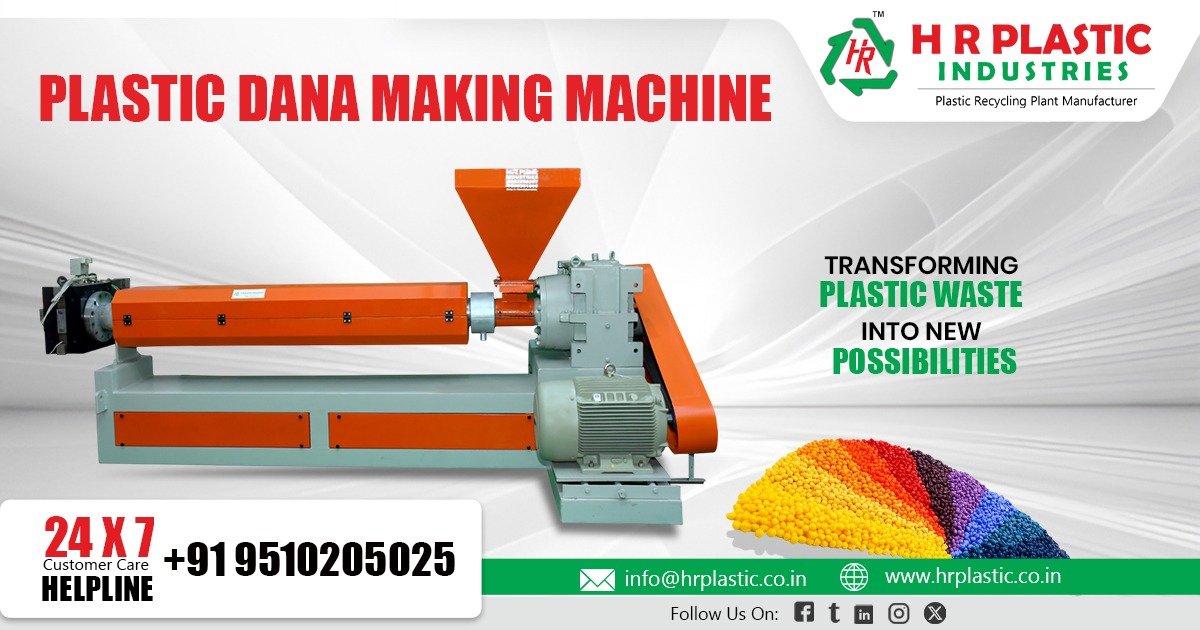

How a PVC Extruder Machine Works:

Feeding: PVC resin in powder or pellet form is fed into the extruder barrel through a hopper.

Melting & Conveying: Inside the heated barrel, a rotating screw conveys the material forward. The combination of heat (from heaters) and shear friction (from the screw’s rotation) melts the PVC.

Mixing & Homogenizing: As the molten PVC moves along the screw, it is thoroughly mixed and homogenized, ensuring uniform consistency.

Pressurization: The screw builds up pressure, forcing the molten PVC through a die at the end of the barrel.

Forming: The die shapes the molten PVC into the desired profile (e.g., pipe, sheet, profile).

Cooling: The newly formed PVC product exits the die and enters a cooling system (usually water baths or air cooling) to solidify its shape.

Haul-off & Cutting: A haul-off unit pulls the solidified product at a consistent speed, and a cutting unit precisely cuts it into predetermined lengths.

Uses of PVC Extruder Machines

PVC Extruder Machines are fundamental to the production of a vast array of PVC products, including:

PVC Pipes: Used for plumbing, drainage, electrical conduits, and agricultural irrigation.

Profiles: Window and door frames, siding, decorative trim, fencing, and decking.

Sheets & Films: For packaging, signage, construction materials, and flooring.

Cables: Insulation and sheathing for electrical cables.

PVC Granules/Pellets: Reprocessing of PVC waste or compounding new PVC formulations.

Medical Tubing: Specialized PVC tubing for various medical applications.

Applications of PVC Extruder Machines:

Construction Industry

Automotive Industry

Electrical Industry

Agriculture

Packaging Industry

Medical Sector

Consumer Goods

FAQs:

Q1: Do you provide installation and training for your PVC extruder machines in the USA?

A1: Yes, as a leading exporter, we offer comprehensive installation and commissioning services at your facility in the USA.

Q2: What kind of after-sales support do you offer?

A2: We provide extensive after-sales support, including technical assistance, spare parts supply, and remote troubleshooting.

Q3: Can your PVC extruder machines process different types of PVC compounds?

A3: Yes, our machines are designed to handle various PVC compounds, including rigid PVC (RPVC) and flexible PVC (FPVC), with appropriate adjustments and die configurations.

Q4: Are your machines energy-efficient?

A4: We incorporate advanced motor controls, efficient heating systems, and optimized screw designs to minimize energy consumption and reduce your operating costs.

Q5: How do you ensure the quality of your machines for export?

A5: We adhere to stringent quality control standards throughout the manufacturing process. Each machine undergoes rigorous testing and inspection before shipment to ensure it meets international quality benchmarks.

Q6: What are the payment terms for international orders?

A6: Our payment terms for international orders are typically discussed during the quotation process.

H.R. Plastic Industries is Exporter of PVC Extruder Machine in USA including a location in Alabama, Alaska, Arizona, Arkansas, California, Colorado, Connecticut, Delaware,

Florida, Georgia, Hawaii, Idaho, Illinois, Indiana, Iowa, Kansas, Kentucky, Louisiana, Maine, Maryland, Massachusetts, Michigan, Minnesota, Mississippi, Missouri, Montana,

Nebraska, Nevada, New Hampshire, New Jersey, New Mexico, New York, North Carolina, North Dakota, Ohio, Oklahoma, Oregon, Pennsylvania[B], Rhode Island, South Carolina,

South Dakota, Tennessee, Texas, Utah, Vermont, Virginia, Washington, West Virginia, Wisconsin, and Wyoming.

Contact us today for more information and to place your order!

View Product: Click here