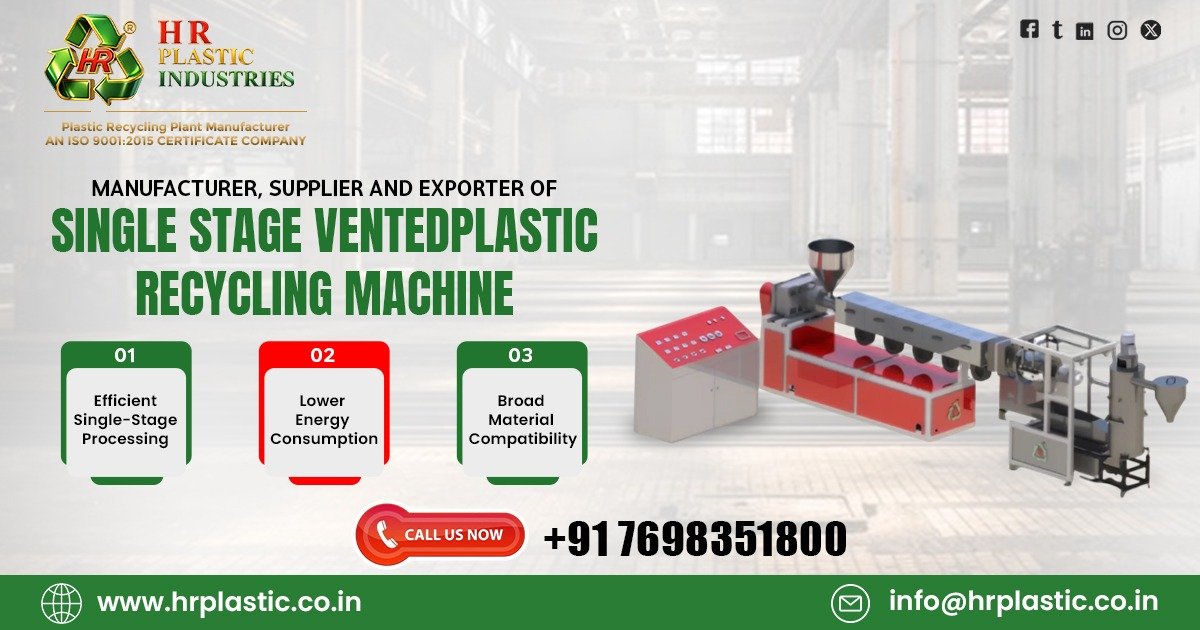

H.R. Plastic Industries is a trusted Indian Manufacturer, Supplier and Exporter of Single Stage Vented Plastic Recycling Machine in Indonesia.

Our Manufacturing unit is based in Ahmedabad, Gujarat, India.

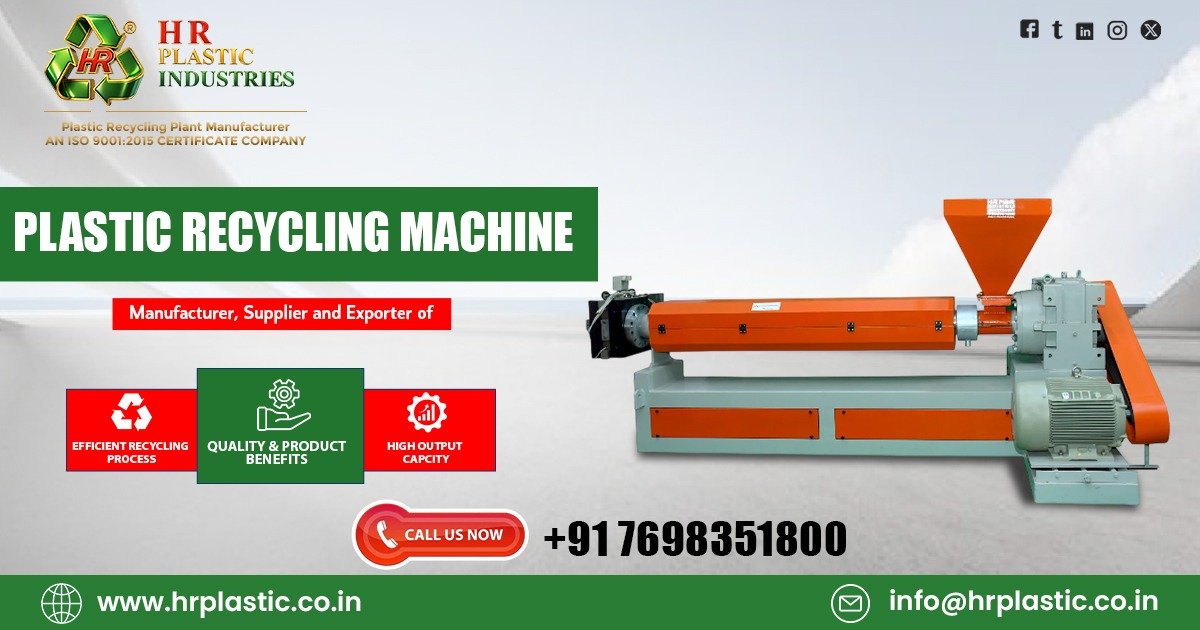

Established in 1987, H.R. Plastic Industries is a leading manufacturer specializing in a wide range of machinery, including Plastic Dana Making Machines, PVC Garden Pipe Making Machines,

Plastic Scrap Grinder Machines, Plastic Granules Making Machines, Semi-Automatic Tea Dryer Machines, Die Face Cutters, and more.

We are committed to meeting customer expectations by delivering superior quality products tailored to their satisfaction.

Our business is built on strong ethical values and complete transparency, fostering long-lasting and trustworthy relationships with our clients.

- 37+ years of industry experience

- 100+ happy customers

- 25+ completed projects

- 30+ skilled team members

- 150+ active clients

Why Choose Our Single Stage Vented Machine?

- Backed by H.R. Plastic Industries, established in 1987, known for quality, reliability, and customer-centric solutions.

- Single-stage process offers simplicity, lower space requirement, and cost-effectiveness.

- High-quality output:

- Degassed, clean plastic pellets or strands with low moisture and contaminants.

- Energy-efficient and compact—designed for optimal operation with reduced power consumption.

- User-friendly controls and automation for seamless operation and maintenance.

Work of Single Stage Vented Plastic Recycling Machine

- Utilizes a vented extruder system to effectively melt and degas plastic waste in a single continuous process.

- Feed waste plastic (e.g., film scrap, post-industrial or post-consumer material) directly into the machine.

- The venting system allows moisture and volatiles to escape, improving material quality.

- Features components such as:

- Strand pelletizer or die face cutter (DFC) for shaping the melted plastic.

- Water cooling bath with air knife to solidify and cut strands cleanly.

- Material screw feeder and electrical control panel ensure consistent and controlled operation.

Features:

- Single-stage vented extruder – efficient melting and degassing in one step.

- Strand pelletizer/DIE face cutter (DFC) system—formats output into pellets or strands.

- Integrated water cooling bath and air knife—ensures rapid cooling and clean pellet formation.

- Material screw feeder—precise and stable feeding of plastic input.

- Comprehensive electrical panel—easy control, safety, and process adjustment.

Technical Specification

| Plant Model | HRPI-75 | HRPI-90 | HRPI-100 | HRPI-110 | HRPI-120 |

| OUTPUT ARTICLE WASTE (LDPE/HDPE/PP) | 80-110 KG/HR | 130-160 KG/HR | 160-200 KG/HR | 220-280 KG/HR | 350-450 KG/HR |

| Running Load | 37KW | 50KW | 44KW | 52KW | 85KW |

Uses

- Recycling film scrap, post-industrial or post-consumer plastic in Indonesian facilities.

- Ideal for:

- Packaging, film, and bag manufacturers

- Plastic product manufacturers (pipes, containers, etc.)

- Municipal recycling set-ups

- Produces high-quality pellets or strands that are suitable for reuse in:

- Injection molding

- Extrusion of sheets, films, or pipes

- Other plastic processing applications

FAQs:

Q1. What types of plastic can this machine process?

– Compatible with a variety of thermoplastics such as LDPE, HDPE, PP, BOPP, PET, and mixed industrial films—depending on customer needs and configurations.

Q2. What output capacities are available?

– Available in multiple output capacities—ranging from small-scale (around 80–120 kg/hr) to higher throughput options (up to 1000 kg/hr or more) based on model and setup.

Q3. Does the machine require special power supply?

– Typically runs on a three-phase power supply, around 380V–440V. Specifications vary by capacity.

Q4. Is installation and training provided?

– Yes, H.R. Plastic Industries offers full installation support and operator training to ensure seamless start-up and safe operations.

Q5. Is customization available for local markets like Indonesia?

– Absolutely. The machine can be customized to align with feedstock types, space constraints, and desired output specifications to suit local recycling needs.

H.R. Plastic Industries is an Exporter of Single Stage Vented Plastic Recycling Machine in Indonesia including locations in Semarang, Kota Ambon, Banda Aceh, Jakarta, Medan, Palembang,

Bandar Lampung City, Pekanbaru, Surabaya, Bandung, Padang, Kendari, Yogyakarta, Samarinda City, Pontianak, Mataram City, Jayapura, Manado, Bengkulu, Makassar, Batam, Banjarmasin,

Malang, Denpasar, Tangerang, Bekasi, Depok City, Kupang, Palangkaraya, Bogor City, South Tangerang, Balikpapan, Baubau, Tanjung Pinang, Lhokseumawe, Palu City, Surakarta City,

Pangkalpinang, Bukittinggi, Binjai, Blitar, Batu, Dumai, Kediri, Tebing Tinggi City, Metro, Salatiga, Mojokerto, Prabumulih, Lubuklinggau, Bontang and many more.

Feel free to contact us for more information and inquiries.

View Product: Click here