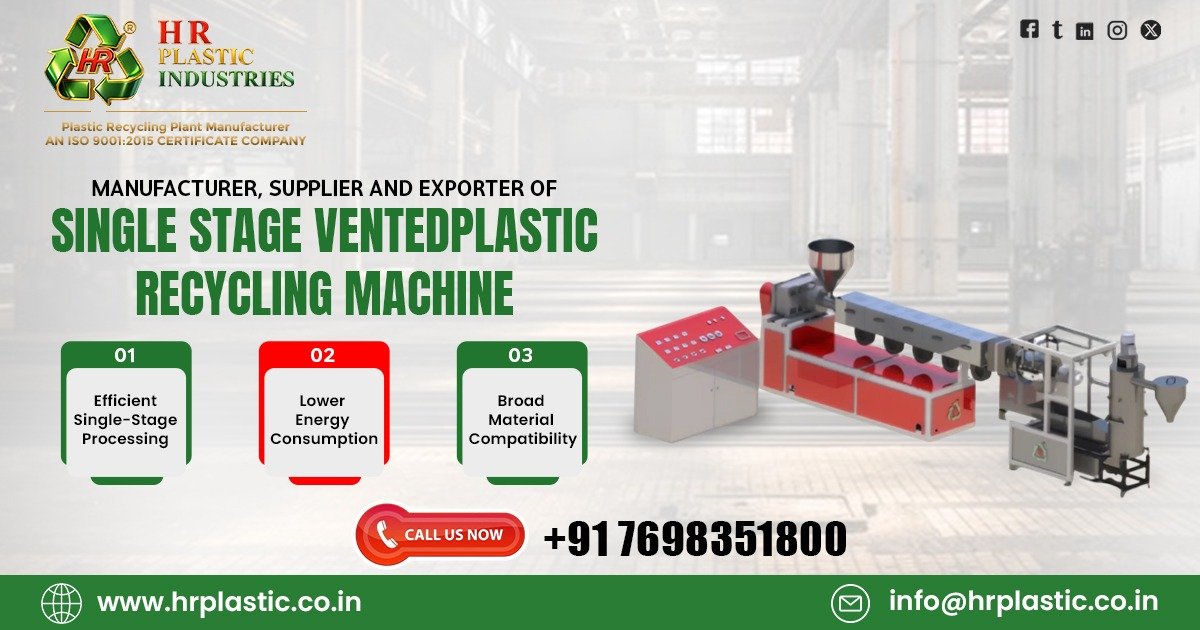

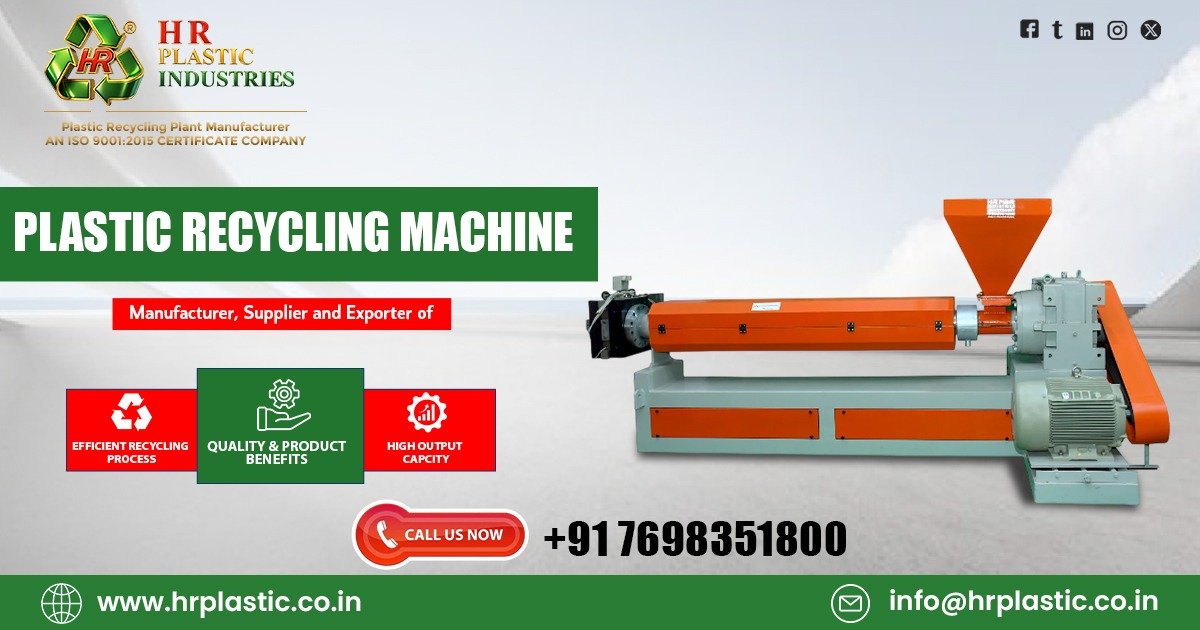

H.R. Plastic Industries is a reliable Manufacturer, Supplier and Exporter of Single Stage Vented Plastic Recycling Machine in United Kingdom.

Our Manufacturing unit is based in Ahmedabad, Gujarat, India.

The Single Stage Vented Plastic Recycling Machine is designed to recycle various types of plastic waste in one continuous process.

It works by melting plastic scrap in a single extrusion stage, where the vented barrel effectively removes moisture, gases, and contaminants from the molten plastic.

This venting process improves the quality of the recycled plastic pellets, ensuring consistency and durability.

The machine’s efficient screw design ensures thorough melting and homogenization of plastic materials, making it ideal for recycling polymers such as PET, HDPE, LDPE, PP, and more.

Features of Single Stage Vented Plastic Recycling Machine

- Single-stage extrusion with venting: Combines melting, filtering, and venting in one process for streamlined operations.

- High-performance screw design: Ensures effective plastic melting and gas venting.

- Energy-efficient motors and heaters: Minimizes power consumption while maintaining optimal processing conditions.

- Robust construction: Made with premium materials to withstand continuous industrial use.

- User-friendly control panel: Allows easy monitoring and adjustment of processing parameters.

- Versatile compatibility: Suitable for a wide range of plastic types.

- Compact footprint: Ideal for factories with limited space.

Technical Specification

| PLANT MODEL | HRPI-75 | HRPI-90 | HRPI-100 | HRPI-110 | HRPI-120 |

| OUTPUT ARTICLE WASTE (LDPE/HDPE/PP) | 80-110 KG/HR | 130-160 KG/HR | 160-200 KG/HR | 200-280 KG/HR | 350-450 KG/HR |

| RUNNING LOAD | 37 KW | 50KW | 44KW | 52KW | 85KW |

Application

The Single Stage Vented Plastic Recycling Machine from H.R. Plastic Industries is ideal for:

- Recycling plastic bottles and containers.

- Processing post-consumer and post-industrial plastic scrap.

- Manufacturing recycled plastic pellets for use in injection molding, blow molding, and extrusion.

- Waste management companies seeking efficient plastic waste conversion.

- Plastic manufacturing industries aiming to reduce raw material costs.

FAQs:

Q1: What types of plastics can this machine recycle?

A: The machine can recycle various plastics including PET, HDPE, LDPE, PP, and more.

Q2: Is the machine suitable for small-scale operations?

A: Yes, the compact design makes it suitable for both small and large-scale recycling plants.

Q3: How does the venting system improve recycled plastic quality?

A: The venting system removes moisture and gases during extrusion, preventing defects and ensuring stronger pellets.

Q4: What kind of maintenance is required?

A: Routine cleaning and periodic checks of screws and heaters are recommended to maintain optimal performance.

Q5: Does H.R. Plastic Industries provide installation and after-sales support?

A: we offer complete installation, training, and maintenance support for our customers across the UK.

H.R. Plastic Industries is an Exporter of Single Stage Vented Plastic Recycling Machine in United Kingdom including locations in London, Birmingham, Portsmouth, Southampton, Nottingham, Bristol, Manchester, Liverpool, Leicester, Worthing, Coventry, Belfast, Bradford, Derby, Plymouth, Westminster, Wolverhampton, Northampton, Norwich, Luton, Solihull, Islington, Aberdeen, Croydon, Bournemouth, Basildon, Maidstone, Ilford, Warrington, Oxford, Harrow, West Bromwich, Gloucester, York, Blackpool, Stockport, Sale, Tottenham, Cambridge, Romford, Colchester, High Wycombe, Gateshead, Slough, Blackburn, Chelmsford, Rochdale, Rotherham, Walthamstow, Basingstoke, Salford, Hounslow, Wembley, Worcester, Hammersmith, Rayleigh, Hemel Hempstead, Bath, Hayes, Darlington, Hove, Hastings, Watford, Stevenage, Hartlepool, Chester, Fulham, Nuneaton, Ealing, Aylesbury, Edmonton, Saint Albans, Burnley, Batley, Scunthorpe, Dudley, Brixton and many more.

For more information and inquiries, feel free to contact us.

Visit: www.hrplastic.co.in

Email: info@hrplastic.co.in, sales@hrplastic.co.in

Call: +91 95102 05025

View Product: Click here