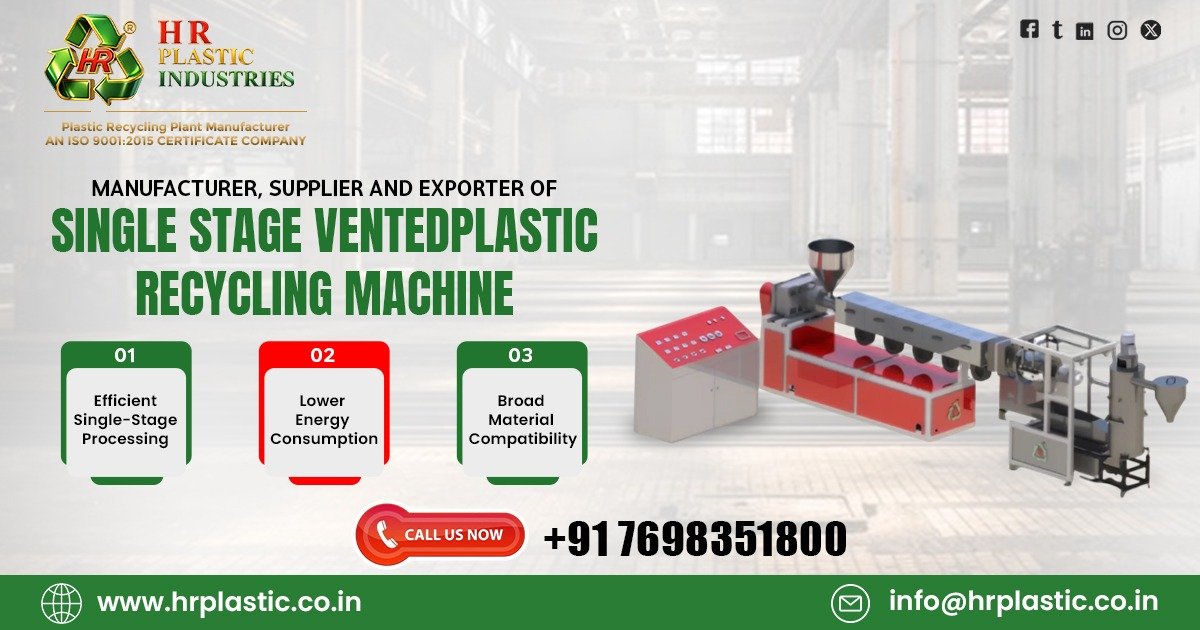

H.R. Plastic Industries is reliable Manufacturer, Supplier of Plastic Granules Making Machine in Gujarat, India.

Our Manufacturing unit is based in Ahmedabad, Gujarat, India.

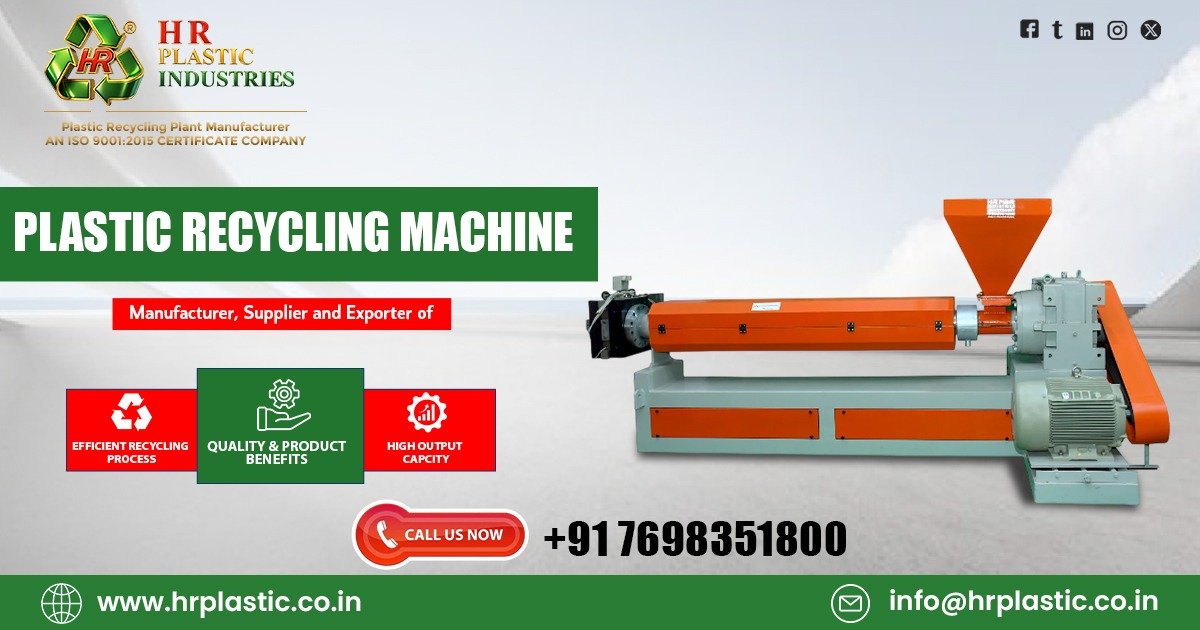

A Plastic Granules Making Machine actively converts plastic waste into reusable granules for manufacturing and recycling purposes.

It provides industries with an eco-friendly solution to plastic waste management, reducing environmental pollution while producing cost-effective raw material.

Their robust construction ensures durability, high performance, and long-term reliability in industrial recycling operations.

We design these machines to handle continuous operation, maintain consistent output quality, and provide precise control over extrusion, cooling, and cutting processes.

Why Choose Plastic Granules Making Machines from H.R. Plastic Industries?

Choosing the right machine is crucial for efficiency, quality, and long-term profitability. Here’s why our machines stand out:

• High-Quality Engineering – Built with robust materials and precision engineering for long-lasting performance.

• Energy Efficient – Designed to consume minimal power while maximizing output.

• User-Friendly Operation – Simple to operate, reducing training time and operational errors.

• Customizable Options – Available in different capacities and specifications based on client needs.

• Reliable After-Sales Service – Dedicated support to ensure smooth operation and minimal downtime.

Work of a Plastic Granules Making Machine

A Plastic Granules Making Machine recycles various plastic wastes, including LDPE, HDPE, PP, and PET, into high-quality reusable granules.

Working Process:

- Feeding: The machine loads plastic waste through a hopper or conveyor system for continuous processing.

- Melting: The fed plastic is melted uniformly within the extruder using controlled heating zones.

- Filtration: The molten plastic passes through specialized filters to remove impurities, ensuring clean and pure material.

- Extrusion: The filtered molten plastic is extruded into uniform strands of consistent diameter.

- Cooling: The extruded strands are cooled in a water bath to solidify them effectively.

- Cutting: Finally, the cooled strands are cut into uniform plastic granules, ready for reuse in manufacturing processes.

Features of Our Plastic Granules Making Machines

High Output Efficiency – Processes large volumes of plastic quickly.

Uniform Granules Production – Ensures consistent size and quality.

Durable Build – Made from high-grade stainless steel and components for long service life.

Advanced Extrusion Technology – Smooth and efficient plastic melting and extrusion.

Automatic Cutting System – Produces uniform granules with minimal manual intervention.

Easy Maintenance – Designed for quick cleaning and maintenance.

Low Noise Operation – Operates smoothly with minimal noise.

Energy Efficient – Optimized for lower electricity consumption.

Applications of Plastic Granules Making Machine

• Plastic recycling plants

• LDPE, HDPE, PP, PET waste processing

• Manufacturing of plastic sheets, bottles, and containers

• Industrial granule production for molding and extrusion

• Plastic pipe and packaging material production

• Environmental sustainability projects and waste management

• Reuse of factory scrap and post-consumer plastic waste

• Plastic furniture, toys, and household goods manufacturing

FAQs – Plastic Granules Making Machine

Q. What types of plastic can be processed?

A. Our machines process LDPE, HDPE, PP, PET, and other thermoplastic materials.

Q. Can the machine produce uniform granules?

A. Yes, the automated extrusion and cutting system ensures consistent and uniform granule size.

Q. Is it energy-efficient?

A.Yes, the machine is designed for optimal energy consumption without compromising output.

Q. Does H.R. Plastic Industries provide technical support?

A. Yes, we offer complete guidance for installation, operation, and maintenance of the machines.

H.R. Plastic Industries is a Supplier of Plastic Granules Making Machine in Gujarat, India Including Location Like Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Junagadh, Gandhinagar, Anand, Mehsana, Nadiad, Bharuch, Vapi, Valsad, Navsari, Palanpur, Bhuj, Morbi, Surendranagar, Porbandar, Godhra, Dahod, Himmatnagar, Patan, Junagadh, Kheda, Amreli, Mahesana, Chhota Udepur, Aravalli, Botad, Devbhoomi Dwarka, Gir Somnath, Mahisagar, Panchmahal, Sabarkantha, Surat, Tapi, Anand, Vadodara, Ahmedabad, Rajkot, Jamnagar, Bhavnagar, Valsad, Navsari.

For more information and inquiries, feel free to contact us.

Visit: www.hrplastic.co.in

Email: info@hrplastic.co.in, sales@hrplastic.co.in

Call: +91 7698351800

View Product: Click Here